VR Simulations for Safety Training in Manufacturing companies

Virtual Reality simulation is a comprehensive solution to introducing workplace safety by enabling workers to learn and put their hands on new production & assembly technologies from the comfort of their place…

December 01 2021 6 mins read

What is VR Simulation?

Virtual Reality simulation is a comprehensive solution to introducing workplace safety by enabling workers to learn and put their hands on new production & assembly technologies from the comfort of their place. This is a profound technology for manufacturing organisations to validate imminent decisions in a 360-degree virtual world even before real-time implementation.

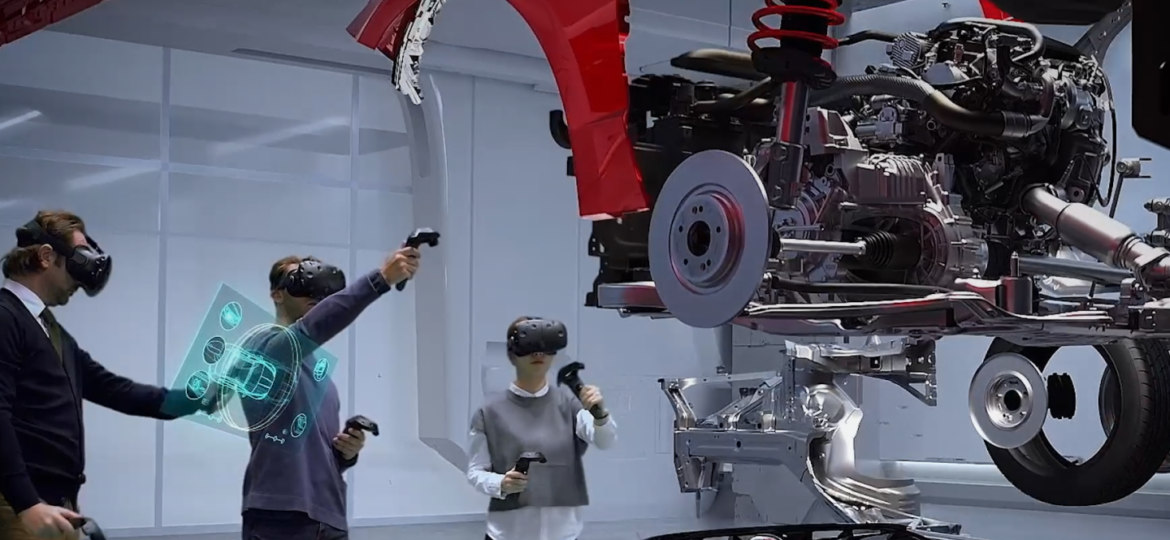

The immense benefit of VR Simulation is owing to its ability to put anyone in 3D simulation in a compact space. Manufacturing organisations are embarking on elevating workplace safety by adopting VR Simulations to facilitate technology training, operations training and workplace safety training.

How do VR Simulations enhance safety in Manufacturing & production firms?

While adopting new technologies or carrying out seamless safety training (protocols) in a manufacturing plant, meeting physical ailments are highly probable. Considering the scenarios and data-backed decisions, manufacturing industries, especially Automobile and Machine making firms, begin to use VR Simulations to train their employees much efficiently than ever before.

With VR-coupled safety training, employees/workers situated across the globe are facilitated to be trained and learnt from a common VR module in an interactive, real-time and safe environment. For instance, manufacturing and production units are prone to fire accidents than any other organisation. Hence, organisations often conduct safety training for their employees to get rid of ailments and safeguard themselves in any occurrences. Usage of VR Simulations can enhance the training and allow them to experience situations in front of their eyes to feel the intensity and complexity.

On the other hand, machine design industries need assembly members to assemble a vast chunk of machine parts with rough metals and sharp edges. When using VR technology, organisations can help workers assemble an intricate product with specific and comprehensive information from the VR Module. Besides, VR Simulation allows manufacturing units to adhere to best practices across all branches in the globe.

Demerits of Physical Training

- Physical hazards

- Mental sickness

- Inability to grasp huge chunk of information

- Cost of training for each location of an organisation

- Inability to maintain global protocols

- No immersive training environment

- Low trainer to employee ratio

Benefits of switching to VR Simulations for training

- Improved learning retention

- Nil human error

- Improved efficiency

- A collaborative and immersive environment

- Fewer implementation challenges

- Can be trained from the comfort of their own space

- Prevent industrial accidents

- Experiencing the assembly environment even before the place is constructed in reality.

How does XR Labs help in VR Safety Training?

When Hyundai Motors, one of the largest automobile organisations, approached us to create a VR Training Simulation for their assembly process, we built a robust VR Simulator to train VR controls, inventory systems and experience real-time assembly configuration.

Contact us to know more and to embark on safety VR Simulations for your manufacturing and production units.

Other Articles

Boost fire safety readiness with immersive VR training for effective fire extinguisher usage. Elevate preparedness and safeguard lives. Learn more.

Discover the differences between 360 Video and VR to find the perfect fit for your business. Make an informed choice for enhanced success.

Discover how VR is revolutionizing enterprise training, enhancing motor learning retention, and creating lasting impact in the workforce.

Let’s build your idea

Turn your idea into a reality with XR Lab’s Augmented Reality solutions. Tell us your idea and we will help you turn it into an Augmented Reality solution.